Customize Glass

Customize Glass

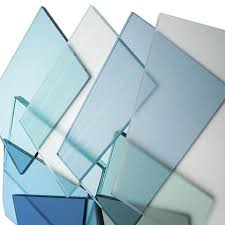

Custom glass refers to glass products that are specifically designed and fabricated to meet unique specifications and requirements. These customizations can involve various shapes, sizes, colors, textures, and functionalities, tailored to individual projects and applications.

Custom glass offers endless possibilities for enhancing the aesthetic and functional qualities of spaces. By tailoring glass products to specific needs and preferences, designers and architects can create unique, high-impact environments.

Types of Custom Glass

- Heat-treated to increase strength.

- Breaks into small, blunt pieces for safety.

- Used in windows, doors, shower enclosures, and tabletops.

- Consists of two or more glass layers bonded with an interlayer (typically PVB).

- Retains fragments if broken, enhancing safety.

- Common in skylights, windshields, and glass floors.

- Surface treated to diffuse light and provide privacy.

- Can be achieved through sandblasting, acid etching, or applying frosted films.

- Ideal for bathroom windows, office partitions, and decorative elements.

- Colored during the manufacturing process to reduce glare and heat gain.

- Offers UV protection and can enhance privacy.

- Used in windows, skylights, and facades.

- Embossed with designs or textures during production.

- Adds visual interest and can obscure visibility for privacy.

- Popular in doors, windows, and interior partitions.

- Two or more glass panes separated by a spacer and sealed to form an insulating airspace.

- Enhances thermal efficiency and sound insulation.

- Used in energy-efficient windows and doors.

Customization Options

Shapes and Sizes

- Glass can be cut to virtually any shape, from simple rectangles to complex curves.

- Customized thicknesses available to meet structural and aesthetic requirements.

Edge Finishing

- Polished edges for a smooth, glossy finish.

- Beveled edges for an elegant, angled finish.

- Seamed or ground edges for safety and functionality.

Color and Tint

- Wide range of colors and tints available to match design aesthetics.

- Custom color matching for specific projects.

Surface Treatments

- Anti-reflective coatings to reduce glare.

- Anti-fingerprint coatings for easier maintenance.

- Low-E coatings to improve energy efficiency.

Etching and Printing

- Custom etching for logos, patterns, and designs.

- Digital printing for high-resolution images and artwork on glass surfaces.

FAQ

Custom glass refers to glass products that are designed and fabricated to meet specific shapes, sizes, colors, textures, and functionalities according to individual project requirements.

- Tempered Glass: Heat-treated for strength and safety.

- Laminated Glass: Multiple layers bonded together for enhanced safety.

- Frosted Glass: Treated for privacy and light diffusion.

- Tinted Glass: Colored to reduce glare and heat gain.

- Patterned Glass: Embossed with designs for visual interest.

- Insulated Glass Units (IGUs): Multi-pane glass for thermal and sound insulation.

Yes, custom glass can be cut into virtually any shape and size to meet the specific needs of your project.

- Aesthetic Appeal: Unique designs enhance visual appeal.

- Functionality: Tailored to meet specific needs such as privacy, safety, and insulation.

- Personalization: Reflects personal style or brand identity.

- Value Addition: Increases the value and functionality of properties.